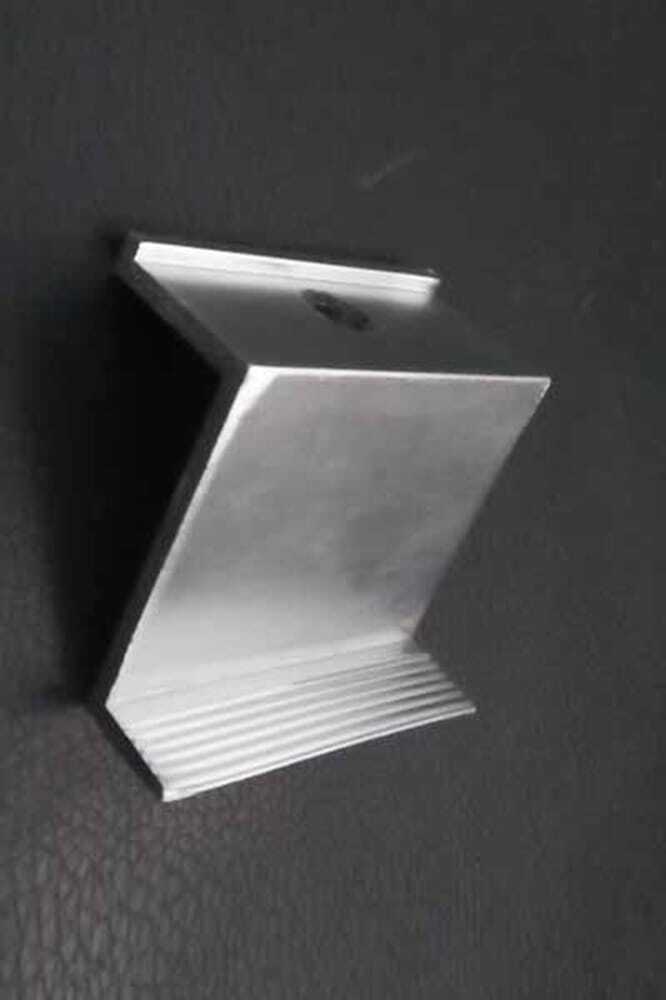

ALUMINIUM PANEL MOUNTING STRUCTURE

Price 3500 INR/ Kilowatt

ALUMINIUM PANEL MOUNTING STRUCTURE Specification

- Maintenance Type

- Maintenance-free

- Features

- Corrosion resistant, Lightweight, High structural strength, Easy installation, Maintenance-free

- Efficiency

- Structural efficiency >95%

- Product Type

- Aluminium Panel Mounting Structure

- Material

- High-grade Aluminium Alloy

- Operating Temperature

- -40°C to 85°C Celsius (oC)

- Max System Voltage

- 1500 V DC (compatible with standard PV systems) Volt (V)

- Color

- Silver

- Type Of Technology

- Extruded Aluminium Mounting

- Installation Type

- Roof-top / Ground Mount / Customized

- Fastener Material

- Stainless Steel (SS304/SS316)

- Surface Treatment

- Anodized / Mill Finish

- Fire Resistance

- Yes, non-combustible material

- Grounding Provision

- Integrated grounding solution

- Compatible Panel Type

- Framed & Frameless PV Modules

- Wind Load Capacity

- Up to 200 km/h (project specific)

- Packaging

- Knock-down/flat pack for easy transport

- Environmental Suitability

- Suitable for coastal/high humidity locations

- Snow Load Capacity

- Up to 2.4 kN/m² (project specific)

- Mounting Angle

- Adjustable (10° - 35°, as required)

ALUMINIUM PANEL MOUNTING STRUCTURE Trade Information

- Minimum Order Quantity

- 5KW Kilowatts

- Supply Ability

- 1000 Kilowatts Per Month

- Delivery Time

- 7 Days

About ALUMINIUM PANEL MOUNTING STRUCTURE

An aluminium panel mounting structure is a lightweight, corrosion-resistant framework designed to support and secure aluminium panels, commonly used in cladding, facades, or solar installations. The structure typically consists of aluminium extrusions such as vertical and horizontal rails (also called mullions and transoms), brackets, clamps, and fasteners. These components are precisely engineered and assembled to provide structural integrity, alignment, and aesthetic uniformity. The system is usually anchored to a buildings primary structure using stainless steel bolts or chemical anchors, ensuring strong adhesion while accommodating thermal expansion. In faade applications, a weatherproofing layer like EPDM gaskets or sealants may be applied between the panels and substructure to prevent water ingress. In solar panel systems, the mounting structure is angled appropriately for optimal sun exposure and often includes grounding provisions. The use of aluminium ensures durability, minimal maintenance, and resistance to environmental degradation, making it a preferred choice for modern architectural and industrial applications.Engineered for Reliability

Crafted from high-grade aluminium alloy and using SS304/SS316 stainless steel fasteners, this mounting structure offers superior durability and structural integrity. Its corrosion-resistant finish and fireproof construction ensure long-term safety and resilience, even in coastal or high humidity locations.

Flexibility in Design & Installation

The system supports adjustable mounting angles (1035) and offers customized sizing for various PV panel types, including both framed and frameless modules. With options for roof-top, ground mount, or bespoke installations, it adapts seamlessly to project-specific needs while maintaining over 95% structural efficiency.

FAQs of ALUMINIUM PANEL MOUNTING STRUCTURE:

Q: How is the aluminium panel mounting structure installed?

A: Installation is straightforward due to the knock-down or flat pack packaging format. Components are assembled on-site according to project specifications, using stainless steel fasteners and adjustable brackets to achieve the desired angle (between 10 and 35). The integrated grounding provision ensures safe and efficient installation across various environments.Q: What types of solar panels are compatible with this mounting structure?

A: This aluminium mounting structure is designed for versatility, supporting both framed and frameless photovoltaic (PV) modules. The customized design adapts to the dimensions and requirements of your specific solar panels, ensuring secure integration and maximum efficiency.Q: When should I choose an anodized or mill finish surface treatment?

A: Anodized aluminium is recommended for environments with high humidity or coastal exposure due to its superior corrosion resistance. Mill finish is suitable for general installations where environmental stressors are less severe. Both options provide lasting durability and performance.Q: Where can this mounting structure be used?

A: It is suitable for a range of settings, including rooftop installations, ground-mounted solar farms, and customized projects anywhere in India, especially in challenging environments like coastal or high-humidity areas. Its robust design and environmental suitability make it ideal for both residential and commercial applications.Q: What is the process for customizing the structure to my project requirements?

A: When ordering, provide your PV module specifications and site requirements. The manufacturer will customize the size, length, width, height, mounting angle, and support configuration based on the projects wind and snow load demands. This ensures precise fit and structural integrity for your installation.Q: How does the structure benefit solar panel installations?

A: The structures lightweight, corrosion-resistant aluminium alloy and high structural efficiency (>95%) result in easy handling, reduced maintenance, and extended lifespan for your solar array. Integrated features such as fire resistance and grounding ensure safe, reliable, and cost-effective solar panel operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solar Mounting Structure Category

ALUMINIUM Z CLAMP

Minimum Order Quantity : 100 Pieces

Color : Silver

Size : Standard

Features : AntiCorrosive, Easy Installation, Robust Design

Product Type : Other, Z Clamp

SOLAR MOUNTING STRUCTURE

Price 3500 INR / Kilowatt

Minimum Order Quantity : 5KW Kilowatts

Color : Silver / Metallic

Size : Customizable as per project requirements

Features : Corrosion resistant, High mechanical strength, Easy Installation, Durable Finish, Customizable Designs

Product Type : Other, Solar Mounting Structure

SOLAR MOUNTING STRUCTURE ALUMINUM

Price 400 INR / Kilowatt

Minimum Order Quantity : 3 Kilovolts

Color : White

Size : Standard

Features : Good Quality

Product Type : Other

Panel Mounting tilt angel Structure

Minimum Order Quantity : 10 Pieces

Color : Blue

Size : Standard

Features : Good Quality

Product Type : Other, Panel Mounting tilt angel Structure

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry