SOLAR MOUNTING STRUCTURE

Price 3500 INR/ Kilowatt

SOLAR MOUNTING STRUCTURE Specification

- Maintenance Type

- Low Maintenance

- Features

- Corrosion resistant, High mechanical strength, Easy Installation, Durable Finish, Customizable Designs

- Product Type

- Solar Mounting Structure

- Material

- Hot Dip Galvanized Steel / Aluminium Alloy

- Operating Temperature

- -40C to +85C Celsius (oC)

- Max System Voltage

- Up to 1500 V DC Volt (V)

- Size

- Customizable as per project requirements

- Color

- Silver / Metallic

- Type Of Technology

- Fixed Tilt / Adjustable Tilt / Tracking Type

- Installation Type

- Ground Mounted / Roof Top Mounted

- Life Span

- More than 25 years

- Surface Treatment

- Hot Dip Galvanized / Anodized

- Mounting Arrangement

- Portrait / Landscape

- Wind Speed Resistance

- Up to 60 m/s

- Load Bearing Capacity

- As per project / panel weight

- Maximum Panel Capacity

- Custom as required by customer

- Ground Clearance

- Typically 500 mm to 1800 mm (customizable)

- Design Standard

- Complies with IS/ASTM/IEC standards

- Coating Thickness

- Minimum 65-80 microns (Hot Dip Galvanized)

- Fire Resistance

- High

- Structure Type

- Pre-Fabricated, Modular

- Fastener Type

- Stainless Steel, Anti-corrosive

SOLAR MOUNTING STRUCTURE Trade Information

- Minimum Order Quantity

- 5KW Kilowatts

- Supply Ability

- 1000 Kilowatts Per Month

- Delivery Time

- 7 Days

About SOLAR MOUNTING STRUCTURE

Types of Solar Mounting Structures

-

Rooftop Mounting Structures

-

Flat Roof Mounts Panels are mounted on tilted frames.

-

Sloped Roof Mounts Panels follow the roof angle or use rails.

-

Ballasted Systems Non-penetrating, use weight to hold down the structure.

-

-

Ground-Mounted Structures

-

Fixed Tilt Mounts Panels are set at a fixed angle.

-

Adjustable Tilt Mounts Angle can be manually changed seasonally.

-

Pole-Mounted Panels are mounted on single or multiple poles.

-

Tracking Systems:

-

Single-Axis Tracker Follows the sun from east to west.

-

Dual-Axis Tracker Follows both the suns daily and seasonal movements.

-

-

Superior Corrosion and Weather Resistance

This mounting structure uses hot dip galvanized or anodized finishes with a coating thickness of 6580 microns. Such robust surface treatments ensure high resistance to rust and environmental degradation, supporting a product lifespan of over 25 years even under extreme weather conditions.

Customizable Design and Easy Installation

Our pre-fabricated, modular system allows for rapid installation and seamless integration with various types of solar panels. The structure supports both portrait and landscape mounting arrangements, and all dimensions, ground clearance, and load capacities are fully customizable to suit project-specific needs.

Compliance with Global Standards for Safety

Engineered as per IS/ASTM/IEC standards and designed to withstand wind speeds up to 60 m/s, this mounting structure offers high fire resistance and operates reliably in ambient temperatures ranging from -40C to +85C. Its robust construction ensures safety and long-term stability for your solar installation.

FAQs of SOLAR MOUNTING STRUCTURE:

Q: How is the solar mounting structure installed, and what types of installations does it support?

A: The structure is shipped pre-fabricated and modular, allowing for quick and easy on-site assembly. It can be installed on both ground and rooftop surfaces, catering to a range of applications from residential to industrial solar projects.Q: What surface treatments are used to ensure corrosion resistance, and how long does the structure last?

A: The mounting structure undergoes hot dip galvanization or anodization, achieving a coating thickness of 6580 microns. This comprehensive treatment provides superior corrosion resistance, supporting a service life of more than 25 years with minimal maintenance.Q: When should a customized design be considered, and what can be tailored?

A: Custom designs are recommended whenever project-specific needs arisesuch as unique panel sizes, specific ground clearance (500 mm to 1800 mm), or particular site constraints. Panel capacity, mounting orientation (portrait/landscape), and overall dimensions can all be tailored as per customer requirements.Q: Where can this solar mounting structure be used?

A: This structure is suitable for solar panel installation in residential, commercial, and industrial settings, offering flexibility to adapt to diverse environments and varying site conditions anywhere across India and for export markets.Q: What are the benefits of using stainless steel fasteners and hot dip galvanized materials?

A: Stainless steel fasteners and galvanized materials offer excellent resistance against rust and corrosion, increase the mechanical strength of the system, and ensure a durable and secure installation that requires minimal maintenance over its operational life.Q: How does the structure perform in extreme weather and temperature conditions?

A: Designed to withstand wind speeds up to 60 m/s and operating temperatures ranging from -40C to +85C, as well as being fire resistant, the structure offers reliable performance and safety even in harsh or demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solar Mounting Structure Category

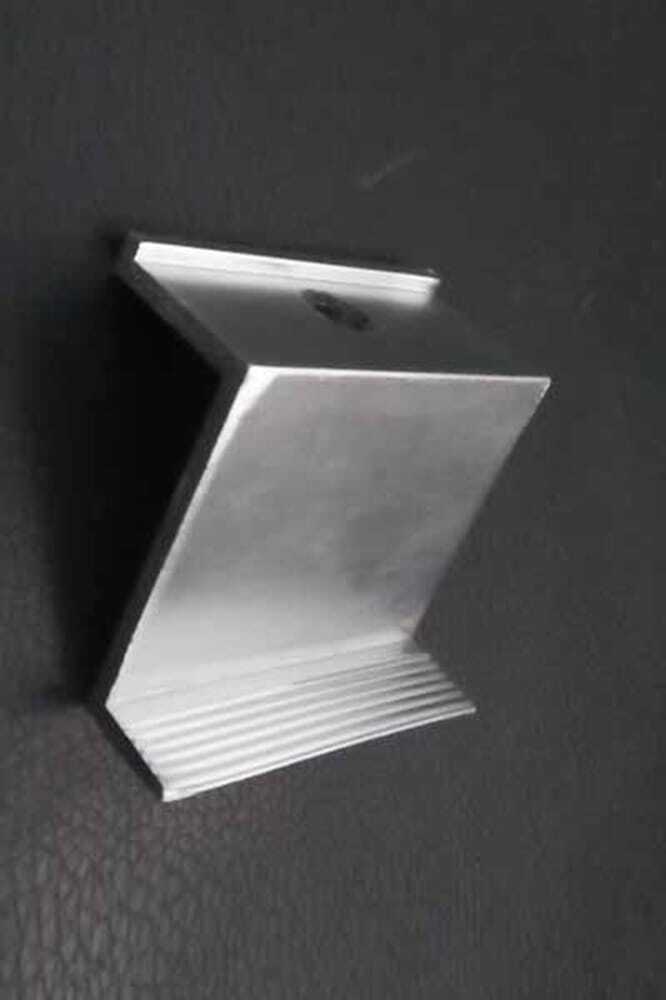

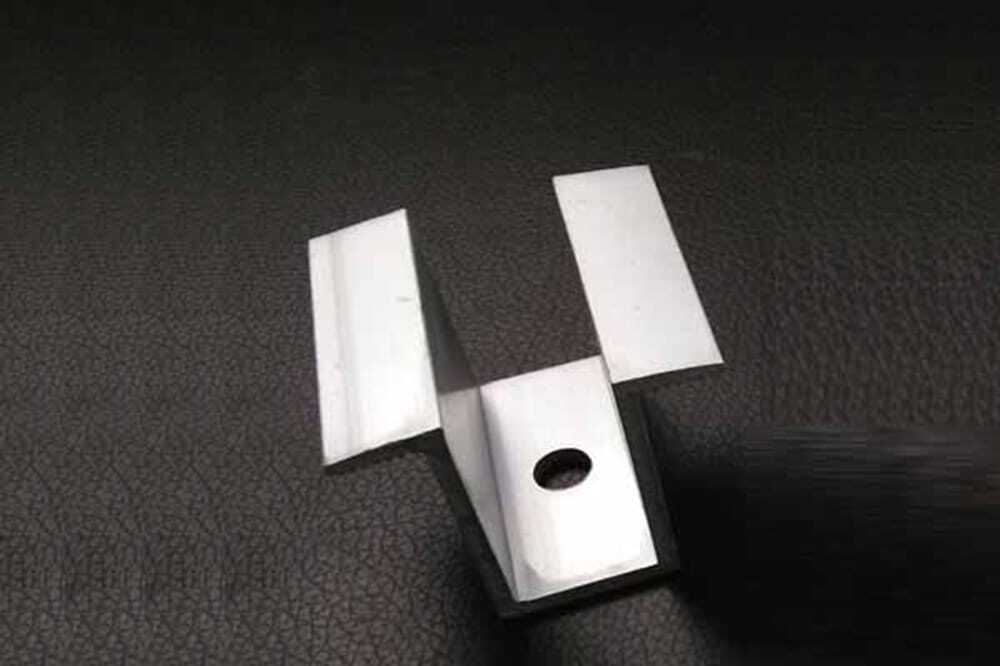

ALUMINIUM Z CLAMP

Minimum Order Quantity : 100 Pieces

Features : AntiCorrosive, Easy Installation, Robust Design

Color : Silver

Material : Aluminium

Size : Standard

ALUMINIUM PANEL MOUNTING STRUCTURE

Price 3500 INR / Kilowatt

Minimum Order Quantity : 5KW Kilowatts

Features : Corrosion resistant, Lightweight, High structural strength, Easy installation, Maintenancefree

Color : Silver

Material : Highgrade Aluminium Alloy

SOLAR MOUNTING STRUCTURE ALUMINUM

Price 400 INR / Kilowatt

Minimum Order Quantity : 3 Kilovolts

Features : Good Quality

Color : White

Material : Aluminum

Size : Standard

SOLAR PANEL MIDDLE CLAMP ALL SIZE

Minimum Order Quantity : 100 Pieces

Features : Corrosionresistant, easy installation, high strength, compatible with most mounting systems

Color : Natural silver (anodized)

Material : Aluminum Alloy (usually 6063T5/T6 or equivalent)

Size : All size (compatible with solar panel thickness 30mm to 50mm, or as specified)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry